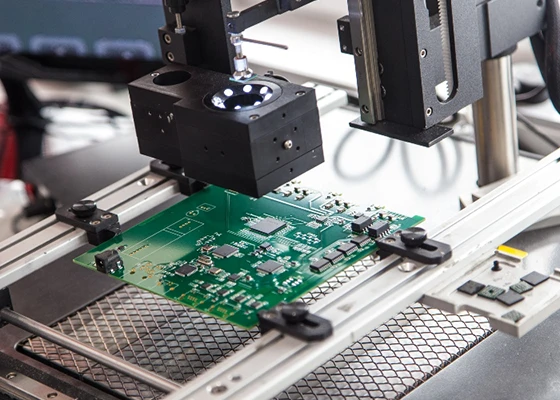

Through-hole PCB assembly remains a widely used technique for assembling electronic components today. This process involves inserting component leads through holes in the PCB and soldering them to the board via wave soldering or hand soldering. At QTECH Technology, our comprehensive through-hole PCB assembly capabilities enable us to effectively serve diverse industries. We handle virtually all types of printed circuit boards, including single-layer PCBs, double-sided PCBs, and high-density multi-layer PCBs.

Contact Us

We have all the knowledge and techniques required for PCB assembly, and all our staff has been rigorously trained to the IPC 610 standard.

We have 3 DIP lines that are equipped with state-of-the-art machines and proficient operators, which allows us to deliver products at very fast turnaround times.

Qtech is fully certified, and our certifications such as ISO9001, ISO13485, IPC610, ROHS, and UL prove our commitment to stringent quality control.

At Qtech, we perform both manual and automated through hole PCB assembly according to different project requirements. Generally speaking, we do hand component insertion and hand soldering for highly complicated assembly projects and use automated through-hole PCBs techniques for small-volume production.

At Qtech, we deliver comprehensive through-hole PCB assembly services tailored to diverse industries, including medical equipment, industrial electronics, precision instrumentation, and defense systems. Our end-to-end capabilities include:

Manual Soldering: Precision hand-soldering for complex or low-volume assemblies.

Dual-Wave Soldering: Automated dual-wave soldering for high-reliability joints.

Manual Component Insertion:Customized hand-insertion of components requiring human dexterity.

Automated Axial/Radial Insertion: High-speed automated placement of axial and radial lead components.

RoHS-Compliant Soldering: Lead-free soldering processes adhering to Restriction of Hazardous Substances directives.

Solder Alloy Flexibility: Utilization of both high- and low-melting-point solder alloys (e.g., Sn96.5Ag3.0Cu0.5 and Sn63Pb37).

Scalable Production: Seamless transition from prototype development to high-volume manufacturing.

Testing & Inspection: Integrated functional testing combined with automated optical inspection (AOI) and X-ray analysis.

Multi-Board Compatibility:Support for diverse PCB types, including metal core PCBs, rigid PCBs, flex-rigid PCBs, FR4 PCBs, and specialized substrates.

In-Circuit Testing: – This testing method is implemented for high-volume production lines, enabling precise verification of individual solder joints and component integrity.

Automated Optical Inspection (AOI) – Abbreviated as AOI, this inspection process ensures the product is free from soldering defects, component misplacement, and BGA (Ball Grid Array) anomalies.

Automated X-Ray Inspection(AXI): – Utilized to identify insufficient solder fills, short circuits, and voids, AXI significantly reduces defect rates while enhancing the reliability of through-hole technology (THT) assemblies.

Burn-in Tests: – These tests assess component reliability under simulated real-world operating conditions to identify early-life failures.

Manual Visual Inspection: – Qualified technicians employ advanced optical equipment to conduct detailed evaluations of solder joint quality and component placement accuracy.