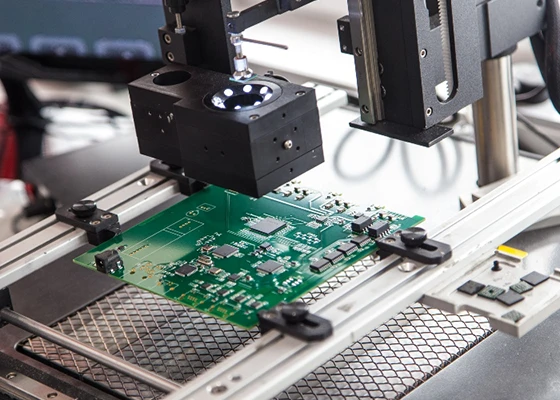

Our BGA assembly services cover a wide range, including prototype development, PCB assembly, component removal, replacement, rework and reballing, PCB inspection, and more. By leveraging our comprehensive service portfolio, we help customers streamline supply chain operations and accelerate product development cycles.

To achieve the highest quality standards for BGA assembly, we use a variety of inspection methods throughout the process, including optical inspection, mechanical inspection, and X-ray inspection. Among these, inspecting BGA solder joints requires X-ray technology. X-rays can penetrate components to examine the solder joints beneath them, enabling inspection of solder joint position, radius, and thickness.

.webp)

.webp)

.webp)

.webp)

.webp)

BGA Rework Station Model No. R8000D The R8000D is an ultra-large-scale high-end vision-aligned precision rework station designed for repairing 5G server motherboards and large-scale switchboards.

.webp)

Desktop Precision Rework Equipment The overall safety design complies with the specifications of GB/T15706-2012 (Mechanical Safety - General Principles for Design - Risk Assessment and Risk Reduction) and the requirements of GB/T1967 (Two-Hand Control Device Safety Design) for dual-hand operation installation.

.webp)

Optical Automatic Rework Machine Model No. R750(for PC) Standard feeder enables automatic feeding and material receiving for small components, featuring an optical rapid centering function that allows suction nozzles to align swiftly with components, enhancing rework efficiency. Equipped with a large-sized infrared carbon fiber heater, it ensures more uniform preheating of PCBA. The hot air system utilizes imported centrifugal fans, delivering constant speed operation and high reliability.

.webp)

Optical Rework Machine Model No. 7220A 1、Real-time temperature display with automatic curve analysis capability. 2、High-definition CCD (2-megapixel) digital imaging, automatic optical zoom system, with manual control integrated with laser red dot alignment. 3、Rapid Heating and Cooling.

Efficient Use of Space BGA PCB layouts optimize available space, enabling higher component density and lighter device production.

Enhanced Thermal Performance Heat generated by components is efficiently transferred through the solder balls. The large contact area further improves heat dissipation, preventing overheating and prolonging component lifespan.

Superior Electrical Conductivity The shortened path between the die and circuit board enhances electrical conductivity. Additionally, the absence of through-holes and full coverage of solder balls across the board minimize unused space.

Simplified Assembly and ManagementBGA assembly uses solder balls to directly attach packages to the board, streamlining the process compared to traditional PCB techniques.

Reduced Lead Damage Risk Solid solder balls in BGA lead manufacturing significantly lower the risk of damage during assembly or operation.

We fully comply with the ISO quality management system and all processes meet the highest quality standards for BGA PCB assembly.

QTECH is capable of handling almost all types of BGA, assembling BGA components from small to large sizes, including fine pitch BGA.

We have a BGA assembly team of professional ipc trained employees to ensure high reliability throughout.