PCB (Printed Circuit Board) corrosion is a common problem faced by electronic devices. Corrosion can lead to malfunctioning circuits, damage to the device, and even render it unusable. In this article, we will explore what PCB corrosion is, what causes it, the types of corrosion that can occur on a circuit board, how to clean it, and how to prevent it from happening in the first place. So, let’s dive in and explore this topic in detail.

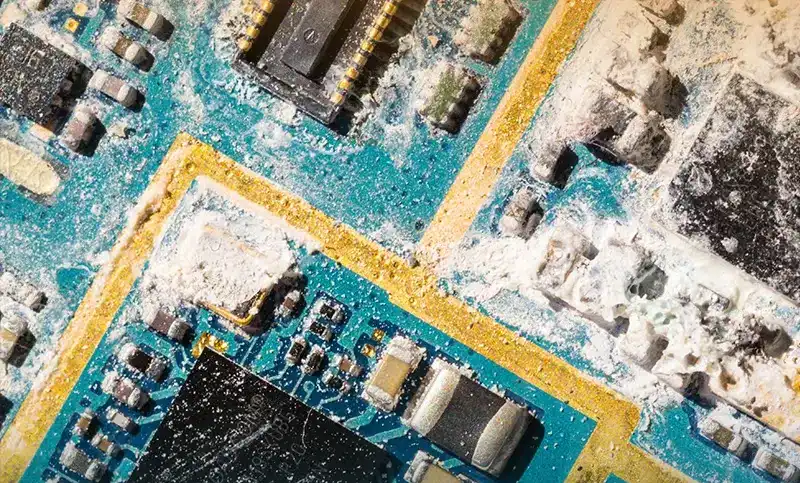

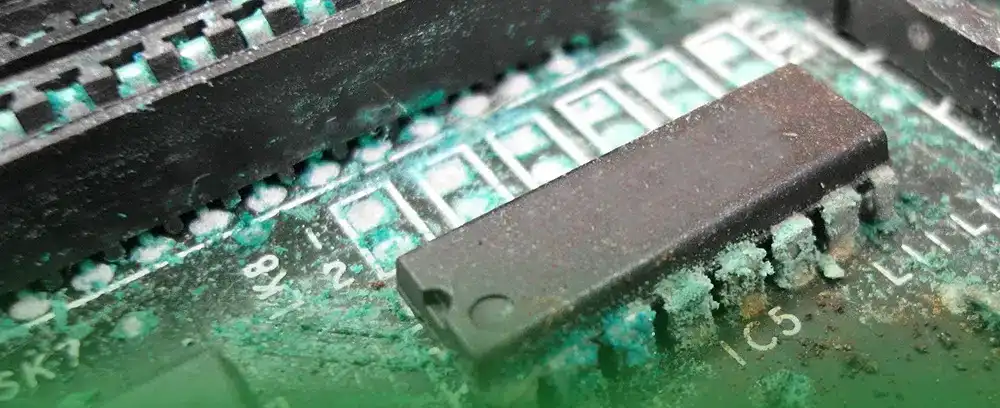

PCB corrosion is the process of metal deterioration on the surface of the printed circuit board. It is a natural process that occurs due to the reaction of the metal with the surrounding environment. Corrosion can occur on the solder joints, contact points, and other metal components present on the PCB. The corrosion can lead to increased resistance and poor contact between the components, which can ultimately cause device failure.

PCB corrosion can be caused by various factors, including:

1.Moisture – Moisture is one of the leading causes of PCB corrosion. Moisture can seep into the board through cracks or gaps in the surface, leading to oxidation of the metal components.

2.Humidity – High humidity levels can also lead to PCB corrosion. The moisture in the air can condense on the surface of the board and cause the metal components to corrode.

3.Chemicals – Chemicals present in the environment, such as acids and alkalis, can corrode the metal components on the PCB.

4.Pollution – Pollution in the air can also contribute to PCB corrosion. Polluted air can contain various chemicals that can react with the metal components on the board.

There are several types of corrosion that can occur on a PCB board, including:

1.Galvanic Corrosion – Galvanic corrosion occurs when two different metals come into contact with each other on the PCB. This can cause an electrochemical reaction, leading to corrosion.

2.Crevice Corrosion – Crevice corrosion occurs in areas of the PCB where there is little or no air flow. This can cause the formation of a localized corrosion cell, leading to corrosion.

3.Pitting Corrosion – Pitting corrosion is a type of corrosion that can occur on the surface of the PCB. It can lead to the formation of small pits or holes on the surface of the board.

There are several materials and tools that can be used to clean circuit board corrosion, including:

1.Isopropyl Alcohol – Isopropyl alcohol is a commonly used cleaning agent for circuit boards. It can dissolve many types of contaminants and can be used to clean the surface of the board.

2.Baking Soda – Baking soda is a mild abrasive that can be used to clean corrosion from the surface of the PCB. It can be mixed with water to form a paste and applied to the surface of the board.

3.Vinegar – Vinegar is an acidic substance that can be used to dissolve corrosion on the surface of the PCB. It can be applied to the surface of the board using a cotton swab or a soft brush.

Here are some valuable tips that you can use to effectively clean PCB corrosion:

1.Identify the Type of Corrosion – Before you begin cleaning the corrosion, identify the type of corrosion that has affected your PCB. This will help you determine the appropriate cleaning agent and method to use.

2.Use the Right Cleaning Agent – Choose the appropriate cleaning agent depending on the type of corrosion that has affected your PCB. Isopropyl alcohol, baking soda, and vinegar are some of the common cleaning agents that can be used to remove PCB corrosion.

3.Be Gentle – When cleaning the affected area, be gentle and avoid applying too much pressure as this can damage the components on the board.

4.Use a Soft Brush or Cotton Swab – Use a soft-bristled brush or a cotton swab to apply the cleaning agent to the surface of the board.

5.Rinse Thoroughly – Rinse the surface of the board thoroughly with water to remove any remaining cleaning agent and dissolved corrosion.

By following these tips, you can clean PCB corrosion safely and effectively, without causing any damage to the board or its components.

Now that we have covered the tips for cleaning PCB corrosion, let’s take a look at the steps involved in cleaning corrosion from circuit boards.

Step 1: Prepare the Cleaning Agent

Prepare the cleaning agent as per the instructions. If you are using isopropyl alcohol, dilute it with water in a 1:1 ratio. If you are using baking soda, mix it with water to form a paste. If you are using vinegar, apply it directly to the surface of the board.

Step 2: Apply the Cleaning Agent

Apply the cleaning agent to the surface of the board using a soft brush or a cotton swab. Ensure that the cleaning agent covers the affected area completely.

Step 3: Wait

Wait for a few minutes to allow the cleaning agent to dissolve the corrosion.

Step 4: Scrub

Gently scrub the affected area with a brush or cotton swab. Do not apply too much pressure as this can damage the components on the board.

Step 5: Rinse

Rinse the surface of the board with water to remove the cleaning agent and the dissolved corrosion.

Step 6: Dry

Dry the surface of the board using a soft cloth or paper towel. Ensure that the board is completely dry before reconnecting it to the device.

Preventing corrosion on PCBs is essential to ensure the longevity of the device. Here are a few tips on how to prevent corrosion on PCBs:

1.Store the Device Properly – Store the device in a dry and cool environment to prevent moisture buildup.

2.Avoid Exposure to Chemicals – Keep the device away from chemicals such as acids and alkalis.

3.Seal the PCB – Seal the PCB with a conformal coating to prevent moisture from seeping into the board.

4.Regular Maintenance – Conduct regular maintenance of the device to ensure that it is functioning correctly.

So that’s about everything you need to know about integrated circuits and how they work. We at Qtech are always ready to give you solid advice about PCBs, PCBA, and ICs. Talk to us today and find out more on what we offer. With over a decade of experience in this field, you’re guaranteed quality always.