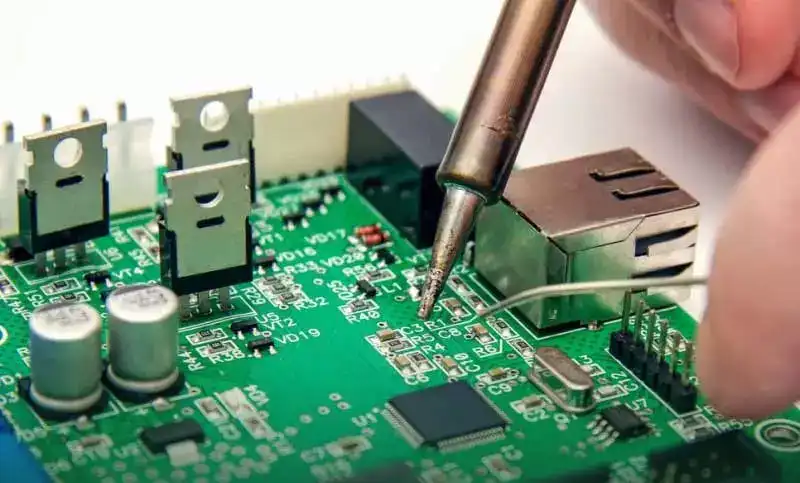

Soldering is a technique used to join two metal surfaces by melting a filler metal, called solder, and then allowing it to cool and solidify, creating a strong bond between the two surfaces. A solder joint is a resulting connection between the two surfaces.

It is one of the most important parts in electronics. It connects two or more pieces of electronic equipment and makes sure that they work together well. Soldering joints are used in many different types of products, such as computers, cell phones, and even electric vehicles.

Solder is the term used to describe a wire or strip of metal that has been melted by heat. It can be applied to any material that is melted and then cooled to form a solid.

In essence, soldering joints is the process of melting and cooling a wire or strip of metal to create a strong bond between two surfaces, often without the use of screws or other fasteners. This versatile technique can be applied to a variety of materials and is commonly used in electronics for its ability to create reliable connections. Through a thorough understanding of soldering, one can unlock new possibilities in manufacturing, repair, and beyond.

Soldering joints are classified into three categories: rigid, semi-rigid, and flexible but there are different types of soldering joints, each with its specific application. Some of the most common types of soldering joints include:

● Lap joint – In a lap joint, the two metal surfaces to be joined are overlapped, and the solder is applied to the overlap area.

● Butt joint – In a butt joint, the two metal surfaces are butted together, and the solder is applied to the joint.

● T-joint – In a T-joint, one metal surface is placed perpendicularly to the other, forming a T shape. The solder is applied to the joint area.

● Corner joint – In a corner joint, two metal surfaces are joined at a right angle. The solder is applied to the joint area.

Solder joints serve several functions, including:

● Electrical conductivity – these joints are commonly used in electronic circuit boards to create electrical connections between different components.

● Mechanical strength – It provides a strong, permanent connection between two metal surfaces.

● Corrosion resistance – The solder material provides corrosion resistance, protecting the metal surfaces from damage.

When it comes to crafting a solid solder joint, several critical factors must be taken into account. Primarily, the joint must be free from any contaminants like dirt, dust, or grime, which could potentially undermine the joint’s strength.

After cleaning the joint, it must be heated to a precise temperature to ensure that the bond is robust and secure. If the joint is intended for electrical use, it’s critical that it has excellent conductivity and is resistant to corrosion and other types of damage, guaranteeing long-lasting strength and reliability.

To create a strong and reliable soldering joint, there are several key characteristics to keep in mind.

● Cleanliness is essential. Any dirt, dust, or other contaminants can weaken the bond and compromise its strength.

● The joint must also be heated to the correct temperature and have sufficient solder for proper coverage and strength. Wetting is another critical factor – the solder must flow and adhere to the surfaces being joined to create a strong bond.

● A smooth surface is also important, as any bumps or bubbles can weaken the joint.

● Consistency is crucial – all joints in a project should have the consistent quality to ensure the final product is strong and reliable.

● If the joint is intended for electrical use, it should have good conductivity, and be resistant to corrosion and other forms of degradation to ensure long-lasting strength and reliability.

A bad solder joint can be caused by a variety of factors, including:

● Insufficient heat: If the soldering iron is not hot enough, the solder may not flow properly and may result in a cold solder joint.

● Too much heat: On the other hand, if the soldering iron is too hot, it can cause the solder to become brittle and crack over time, resulting in a weak joint.

● Incorrect technique: If the soldering iron is not held at the correct angle or if the solder is not applied evenly, it can result in a poor joint.

● Dirty surfaces: If the surfaces being soldered are not properly cleaned and prepared, the solder may not adhere properly and result in a weak joint.

● Wrong solder type: Using the wrong type of solder for the job can also result in loss of product.

One specific type of bad solder joint is a cold solder joint. This occurs when the solder does not properly flow and adhere to the surfaces being joined, resulting in a weak and unreliable connection. To prevent cold solder joints, it is important to make sure that the surfaces being joined are clean and properly prepared, and that the soldering iron is hot enough to allow the solder to flow smoothly.

In addition to the techniques used to prevent cold solder joints, there are other best practices to follow when soldering to ensure strong, reliable connections. Some of these include:

● Use the correct solder for the job. Different types of solder have different melting points and other properties that make them more suitable for certain applications.

● Use flux to help the solder flow and adhere properly.

● Use a high-quality soldering iron with a clean, well-maintained tip.

● Use a magnifying glass or other magnification tools to inspect the joint and make sure it is properly formed.

● Practice proper technique, including holding the soldering iron at the correct angle and applying the solder evenly.

So that’s about everything you need to know about integrated circuits and how they work. We at Qtech are always ready to give you solid advice about PCBs, PCBA, and ICs. Talk to us today and find out more on what we offer. With over a decade of experience in this field, you’re guaranteed quality always.