Electronics manufacturing services (EMS) are offered by a specific class of companies that provide engineering, manufacturing, and other value-added services for Original Equipment Manufacturers (OEMs). In many cases, this term can be interchangeable with Contract Manufacturing Services (CMS) or Contract Electronics Manufacturing (CEM). EMS providers provide a wide scope of services for customers in different industries, the services range from design, manufacturing, and electronic assembly, to quality control, supply chain management, logistics transportation, and after-sales support. EMS companies allow their customers to pay more attention to their core businesses such as research and development, marketing, and sales.

Therefore, many manufacturers choose to cooperate with EMS companies to enhance market competitiveness, and the demand for electronic manufacturing services continues to increase. Qtech, as a leading electronics manufacturer in China, we have witnessed the evolution and rapid development of the EMS industry. In this article, we will bring you a comprehensive portrait of the industry, including its overview, development history, trends, how to choose outsourced electronic manufacturing services, and so on. Let’s dive right in…

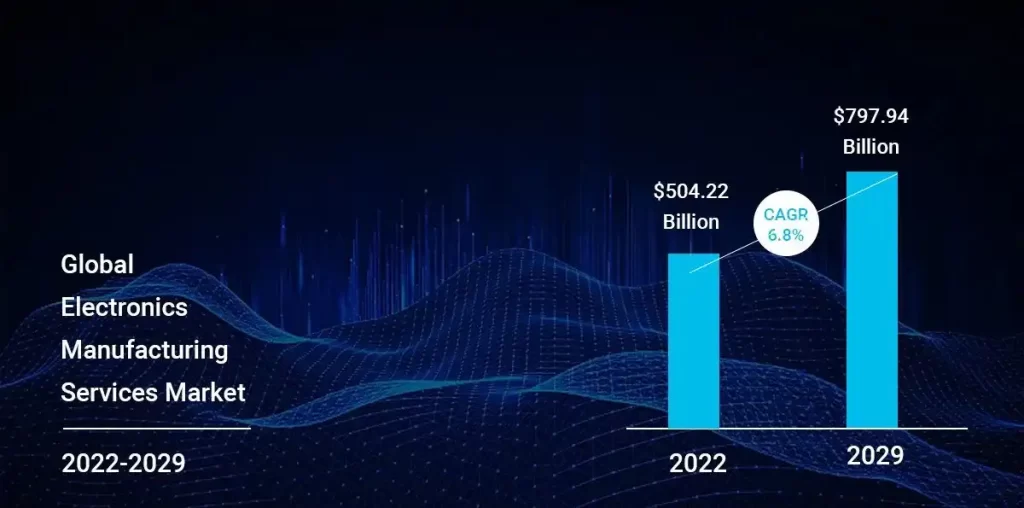

According to statistics, the global electronics manufacturing services market is expected to reach US$504.22 billion in 2022 and increase to US$797.94 billion by 2029, with a CAGR of 6.8% during the forecast period. Among them, the Asia-Pacific region occupies the largest share and plays an important role in the global EMS market. Electronic manufacturing services are widely used in different industries, main industries include automobiles, communications, computers, consumer electronics (smartphones, personal computers, laptops, etc.), industry (automation and Internet of Things), medical care, etc., among which communications and computer hardware industries account for about 59% of the total demand. For more detailed information, please refer to our another blog “Electronic Manufacturing Services (EMS) Market Analysis & Trends”

In general, the EMS market has great potential for development, especially driven by the growing demand for automotive and consumer electronics. With the ever-increasing demand, competition in the industry will also intensify, which will enhance the standards and norms of the entire industry.

The first EMS company was Solectron Corporation, founded in 1977, to provide outsourced services to original equipment manufacturers. At that time, their founders, Roy Kusumoto and Prabhat Jain, found that electronics companies had a huge demand for printed circuit board assembly, so they founded this company integrating design, manufacturing, and after-sales service. Then in the 1880s, the industry experienced the greatest growth and many famous EMS companies were established, including Sanmina Corporation which was established in 1980. With the advent of surface mount technology (SMT), electronics can be assembled quickly. It is also a driving force in the development of the EMS industry. By the mid-1990s, many OEMs began to outsource PCB assembly services to EMS companies to reduce costs, and the advantages of EMS became prominent. In the late 1990s and early 2000s, most original equipment manufacturers sold their assembly lines to EMS suppliers, and the EMS industry also ushered in a wave of consolidation. Large EMS companies began to acquire factories and small-scale EMS companies. Among them, Solectron Corporation was acquired by Flex in 2007.

Printed circuit board assembly (PCBA) is one of the most important services provided by electronic manufacturing service providers, and it is also a very critical link in electronic manufacturing. It refers to a process that solders electronic components to the board by using SMT or though-hole technology, SMT is more popular in recent years though, as it allows manufacturers to assemble components more efficiently. However, building a precision assembly line can be costly, not every manufacturer can afford it, especially for those startups. Therefore, many manufacturers outsource PCBA services to EMS providers who can assembly complex circuit boards at fast turnaround times and competitive prices. In addition, many EMS companies can provide integrated electronics assembly services. Besides PCBA, some of them are capable of handling cable and wire harness assembly, box build assembly, electro-mechanical assembly, and other services.

The technicians and engineers at EMS companies specialize in product management, manufacturing processes, and quality control. They work with customers closely to support them within the whole product life cycle, to turn their concepts into products on the shelf. Normally, engineering services offered by EMS companies include electronics design, PCB layout design, housing design, BOM and revision management, prototyping, DFM, and DFX services. Also, they cooperate with product certification entities such as ETL, TUV, or UL, to help manufacturers to obtain various certifications required for product circulation in the international market.

New product introduction (NPI) is one of the most important processes in electronics manufacturing, and it refers to the process that covers steps from initial conception, and prototyping to the final product. Before mass production, EMS providers will perform a comprehensive and in-depth evaluation of the new product, including P-FMEA evaluation, program preparation, trial production, and material verification, to find out potential risks. And in some cases, they also consider the design, construction, and preparation of any necessary product-specific tooling or fixtures. Working with an EMS provider who is experienced in NPI can bring your products to the market successfully within a short time.

Based on bill of materials (BOMs) and product specification, EMS providers help customers to purchase all materials and components needed. For some complicated products, hundreds of components may be required, which will undoubtedly make the supply chain very complicated. In this case, an EMS company can help you optimize your supply chain, finance on behalf of the OEM, help you source high-quality materials within your budget, and optimize service costs for your customers. Therefore, cooperating with excellent EMS companies can help OEMs bring greater profits. Moreover, electronics manufacturing services providers can provide inventory management services according to your needs.

In order to ensure that the products delivered to customers meet the quality requirements, EMS suppliers will conduct product testing. This is an indispensable link to avoid huge losses caused by product quality problems, including economic losses and damage to product and company reputation. They can directly use the equipment provided by customers to conduct various tests, including flying probe tests, burn-in tests, automatic optical inspection, functional tests, and other testing methods.

Partnering with a reliable electronics manufacturing services (EMS) provider offers numerous advantages, and the most significant four advantages are listed below:

For OEM manufacturers without their own production lines, facilities, or skilled production and engineering staff, collaborating with an EMS provider can be the only way to bring a new product to market. EMS providers often make significant investments in infrastructure, technology, and personnel, and they can spread these costs among multiple customers, which means their fixed costs are shared. For OEMs with uncertain demand and fluctuating supply, working with an EMS provider is the most logical and cost-effective solution. Outsourcing helps OEMS save money, and time, and convert fixed costs that are usually very high into variable costs. The less quantity you order, the less you pay.

The need for a highly specialized workforce has become crucial with the changes in technology and customer demands. This requires not only good employee selection and training but also strong engineering expertise. This translates into substantial fixed costs that must be maintained for the assembly operations. By working with a qualified electronic manufacturing provider, the original equipment manufacturer can focus on new product development or marketing instead of spending more time on production and indirect manufacturing competencies. This not only reduces fixed costs, headcount, and personal and recruitment expenses but also minimizes the hassle of managing the production environment.

Dependable electronic manufacturing service providers have extensive experience in managing procurement procedures and collaborating with pre-approved suppliers globally. They have solid planning capabilities and sophisticated ERP systems along with MES platforms to ensure smooth execution of assembly in production. These two components are crucial for managing a cost-effective production process and require expertise that is acquired through years of best practices. With these tools and capabilities, competent electronic manufacturers can respond to customer needs in a flexible and trustworthy way, not only on paper but also in a real production environment. Their knowledge in selecting approved suppliers, sourcing components, and efficiently executing the procurement process results in a well-managed supply chain. Partnering with electronics manufacturing companies frees OEMs from investing in complex IT systems and building supply chain management expertise that requires highly trained staff and long-term expertise. Professional EMS providers, on the one hand, can help to manage the supply chain, and on the other hand, they can aid OEMs to develop effective planning solutions while supervising. They work with material suppliers based on the customer’s specifications and agreements to minimize the client’s excess material and ensure a stable production process.

Late delivery can harm a company’s reputation and business. Partnering with a well-organized electronic manufacturing services provider reduces the risk of orders being delivered late, which could delay the final product delivery. This requires effective collaboration and consideration of the material’s lead times. Working with an EMS company also offers the advantage of leveraging their purchasing power and market position to negotiate more favorable material prices, as well as utilizing production equipment efficiently. The economies of scale result in a decrease in the unit cost of the OEM’s products, leading to additional financial benefits and efficiently-run projects.

Choosing the right Electronics Manufacturing Services partner is crucial in outsourcing. Here are some key factors to consider when making your decision:

Quality is the top priority, and working with an EMS provider with strict quality control measures is essential to protect your reputation and business. You can verify their certifications such as ISO9001, ISO13485, UL, IPC, etc., which show their commitment to quality and compliance with industry standards. Additionally, you can evaluate their quality control process, including their inspection and testing methods, and if they perform 100% inspection before delivery to ensure each product meets expectations and avoid any potential defects.

Why take the chance of having a novice handle your project when you can work with a seasoned electronic manufacturer? When selecting electronic manufacturing companies, it’s essential to consider their experience and proficiency, especially if they have worked on similar projects. Working with experienced companies who understand the demands of various industries ensures that products meet industry standards and eliminate quality concerns. They also have the ability to make accurate market predictions based on prior project experience and adapt to changes.

An outstanding electronic manufacturer should offer not just manufacturing services, but engineering services too. This way, when the company receives your project specifications, they can evaluate if the design is practical, and if not, they can suggest modifications or redo the design. Usually, electronic manufacturing firms employ experienced engineers, who specialize in areas such as production engineering, mechanical engineering, microelectronics, and others, to guarantee that the final product performs optimally.

It’s crucial to understand the types of technologies and facilities utilized by your electronic manufacturer. The use of advanced technologies and facilities leads to more efficient manufacturing compared to outdated ones. With access to the latest technologies, manufacturers can produce high-quality products with increased reliability and speed, boosting market competitiveness. Before making a decision, you can request the manufacturer to supply a list of their equipment or arrange a visit to their manufacturing site to assess the equipment and confirm that their facility and processes are up-to-date with industry standards.

The time it takes to complete a project is crucial, especially for projects that require a large volume of production. To ensure that your product can be launched on schedule, it is necessary to verify that the electronic manufacturer’s turnaround time aligns with your project timeline. To guarantee timely delivery, you need to verify their production capacity. Dependable electronic manufacturers have the ability to complete projects efficiently due to their access to advanced machinery and a well-established global supply chain that provides materials and components promptly.

In last, while selecting an electronic manufacturing firm, it is vital to inquire about its supply chain management. You should determine if they have a dependable and adaptable supply chain system in place. Electronic manufacturers usually partner with various suppliers from across the world to meet the varying demands, avoiding limitations in procurement that may result in project delays. Furthermore, working with multiple suppliers allows them to have up-to-date information about the global market, such as supply shortages and price fluctuations, allowing them to make informed decisions, mitigate risks, and resolve any potential issues.

The electronics manufacturing industry is one of the fastest-growing and constantly evolving industries in the world. With advancements in technology and the increasing demand for electronic devices, this industry is poised for growth and is ripe with opportunities for companies and investors alike. And we have listed the latest 5 trends and opportunities in the electronics manufacturing industry below:

The demand for smart devices such as smartphones, smartwatches, and smart home devices has skyrocketed in recent years, and this trend is expected to continue in the coming years. With the rise of the Internet of Things (IoT), the market for smart devices is expected to grow at a rapid pace, creating a massive opportunity for electronic manufacturers. Companies that are able to produce high-quality and innovative devices that meet the changing needs and demands of consumers will thrive in this industry.

Wearable technology is another trend that is set to revolutionize the electronics manufacturing industry. Wearable devices such as fitness trackers, smartwatches, and virtual reality headsets are becoming increasingly popular, and this trend is expected to continue. As the technology continues to improve and become more affordable, the market for wearable devices is expected to grow, providing a huge opportunity for electronic manufacturers.

5G technology is the latest innovation in the telecommunications industry and is expected to bring about significant changes in the way electronic devices are designed, manufactured, and used. This technology is poised to bring about faster data speeds, lower latency, and improved reliability, which will result in a new generation of devices that are more powerful and more efficient. Companies that are able to develop and manufacture devices that are compatible with 5G technology will have a major advantage in the market.

E-commerce is another trend that is expected to continue to grow, and this growth is expected to drive the demand for electronic devices. As more and more people turn to online shopping, the demand for devices that make the process of shopping easier, such as smartphones and laptops, is expected to increase. This trend will create a huge opportunity for electronic manufacturers to develop and produce innovative devices that meet the changing needs of consumers.

Renewable energy sources such as solar and wind power are becoming increasingly popular, and this trend is expected to continue in the coming years. As more and more people turn to renewable energy sources to power their homes and businesses, the demand for electronic devices such as solar panels and wind turbines is expected to grow. Companies that are able to develop and manufacture innovative devices that are compatible with renewable energy sources will have a major advantage in the market.

The electronics manufacturing industry is a dynamic and constantly evolving industry that is poised for growth and is filled with opportunities for companies and investors alike. Companies that can keep up with the latest trends and can produce high-quality and innovative devices will thrive in this industry. With the rise of smart devices, wearable technology, 5G technology, e-commerce, and renewable energy sources, the electronics manufacturing industry is expected to grow significantly in the coming years, providing a huge opportunity for companies to succeed.

Electronics manufacturing is characterized by its swift pace of development and constant evolution. Providers of flexible solutions that can adapt quickly to these rapid changes will continue to be successful in meeting their customers’ needs.

Qtech Technology keeps pace with the times, and innovation is the driving force for our continuous progress. We have a complete global electronics manufacturing business process, using world-leading equipment and advanced technology to continuously simplify our production process, aiming to help customers solve global electronics manufacturing challenges from design to implementation. We will work closely with you throughout your entire product development lifecycle from concept design, and engineering to manufacturing to enhance your market competitiveness. If you’re looking to start outsourcing your electronics manufacturing services, we’re a great choice. Contact us now to start your project!