As a kind of common capacitor, electrolytic capacitors are essential electronic component that is widely used in electronic circuits, power supplies and audio equipment. They have high capacitance value and store and release electrical energy efficiently. This article aims to provide an overview of electrolytic capacitors, their operating principles, common applications, and important considerations when using them.

Electrolytic capacitor is a capacitor made of an oxide film formed by electrolysis as a medium. Electrolytic capacitors are used in a wide range of electronic applications due to their specific characteristics and capabilities. Here are some common uses of electrolytic capacitors:

● Power Supply Filtering

● Audio Equipment

● Motor Start and Run Circuits

● Industrial Control Systems

● Automotive Electronics

● Electronic Devices and Appliances

Besides, the specific capacitance, voltage rating and other parameters of electrolytic capacitors may vary depending on the application and requirements of the electronic system. Therefore, choosing the right capacitor type and specification is crucial to ensure optimal performance and longevity in any application.

■ Aluminum Electrolytic Capacitors:

These capacitors have an aluminum anode, an aluminum oxide dielectric layer, and a conductive electrolyte. They are economical and offer high power values. They can be divided into non-solid aluminum capacitors and solid aluminum capacitors (aluminum polymer capacitors). The non-solid type has a liquid or gel electrolyte, while the solid type uses a solid polymer electrolyte.

■ Tantalum Electrolytic Capacitors:

Tantalum electrolytic capacitors use tantalum anode, tantalum oxide dielectric and conductive electrolyte. They provide stable capacitance over a wide range of temperatures and frequencies. Tantalum capacitors come in two forms:

solid tantalum electrolytic capacitor, using solid electrolyte and hybrid tantalum electrolytic capacitor, combining tantalum with other capacitor technologies.

Tantalum capacitors can be classified into two subtypes:

● Solid tantalum Electrolytic capacitor

● Tantalum hybrid Electrolytic capacitors

Aluminum electrolytic capacitors are commonly used in electrical circuits and audio equipment, while tantalum electrolytic capacitors are commonly found in highly stable applications such as military equipment and medical equipment.

It is important to consider the specific requirements of your application and consult the manufacturer’s instructions to select the correct electrolytic capacitor.

Electrolytic capacitors offer several advantages and disadvantages that are important to consider when selecting and using them.

Advantages:

•-High capacitance values.

•-Compact size.

•-Cost-effective compared to some other high-capacitance capacitor types.

•-Wide range of voltage options available.

Disadvantages:

•-Polarity sensitivity, requiring correct polarity connections.

•-Limited lifespan compared to other capacitor types, requiring periodic inspection and replacement.

•-Voltage and temperature limitations should not be exceeded.

•-Reliability issues, such as electrolyte drying, increased equivalent series resistance (ESR), or leakage under certain conditions.

It is important to consider these advantages and disadvantages in the context of your specific application and requirements. Careful selection, proper handling and following the manufacturer’s instructions are essential to ensure the safe and reliable operation of electrolytic capacitors.

Determining whether ceramic capacitors or electrolytic capacitors are better depends on the specific requirements and characteristics of the application. Each type has its advantages and disadvantages. Here’s a comparison between the two:

Ceramic Capacitors:

• Advantages: Small size, high capacitance in small physical packages, low ESR and ESL, a wide range of voltage ratings, and good temperature stability.

• Disadvantages: Capacitance may be less stable with temperature changes, affected by DC bias voltage, the potential for microphonic noise, and limited capacitance values compared to electrolytic capacitors.

Electrolytic Capacitors:

• Advantages: High capacitance values available, suitable for applications requiring large capacitance, can handle higher voltage ratings, cost-effective, compact size relative to capacitance, suitable for energy storage and filtering.

• Disadvantages: Extremely sensitive poles, limited lifespan compared to some other types of capacitors, voltage and temperature limitations, and reliability issues under certain conditions.

In summary, ceramic capacitors are often preferred because of their small size, low ESR, and high-frequency efficiency, making them suitable for applications such as decoupling, bypassing, and filtering. On the other hand, electrolytic capacitors are beneficial when high capacitance values, energy storage, or cost savings are required in applications such as power supplies, audio equipment and industrial control systems.

Ultimately, the choice between ceramic and electrolytic capacitors depends on specific requirements, operating conditions, and trade-offs that must be considered for a given application.

Construction of an Electrolytic Capacitor:

● -Anode: The positive terminal is typically made of aluminum.

● -Cathode: The negative terminal containing a conductive electrolyte.

●- Dielectric: Thin oxide layer formed on the surface of the anode, acting as the insulating layer.

● -Electrolyte: Conductive substance filling the capacitor, making contact with the cathode.

Working of an Electrolytic Capacitor:

●- Polarization: Electrolytic capacitors are polarized, requiring the correct connection of positive and negative terminals.

● -Electrolyte Charging: Applying a voltage causes electrons to flow from the cathode to the anode through the electrolyte, resulting in charge accumulation.

● -Electrolyte Layer Formation: An oxide layer forms on the anode’s surface, serving as the dielectric.

● -Capacitance: The surface area of the anode, dielectric thickness, and electrolyte properties determine the capacitor’s capacitance.

●- Energy Storage and Discharge: The capacitor stores electrical energy and can release it when connected to a circuit.

It’s important to follow manufacturer guidelines and consider factors such as polarity sensitivity and voltage/temperature limitations for safe and reliable usage of electrolytic capacitors.

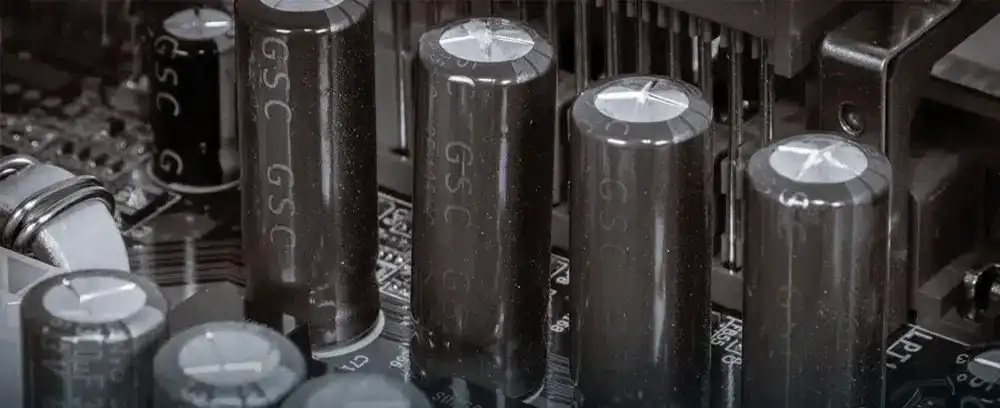

Determining if a capacitor is electrolytic or not can be done through visual inspection or by checking the labelling or markings on the capacitor itself. Here are some ways to identify an electrolytic capacitor:

● Physical Appearance: Electrolytic capacitors typically have a cylindrical or can-like shape and are larger compared to other capacitor types.

● Markings or Labeling: Check for markings or labels on the capacitor indicating its capacitance value, voltage rating, and polarity indicators. Polarity markings (+ and – symbols) suggest that the capacitor is electrolytic.

● Polarity Indicators: Electrolytic capacitors are polarized and have positive and negative terminals. Look for a longer lead or a plus (+) symbol for the positive terminal and a shorter lead or a minus (-) symbol for the negative terminal.

● Manufacturer Datasheets or Specifications: The manufacturer’s datasheets or specifications for the capacitor will provides information about its type, including whether it is electrolytic or not.

By considering these factors, you can determine if a capacitor is electrolytic or of a different type.

● Physical signs: Check for obvious physical markings on the capacitor, such as a longer cable or symbols (+ and -), indicating the positive and negative terminals, respectively.

● Labelling: Look for polarity markings or labels on the capacitor’s body or packaging, which may include symbols (+ and -) or words like “positive” and “negative”.

● Color code: Some electrolytic capacitors have colored bands or stripes on the body, where specific colors represent the anode and cathode.

● Data sheets or specifications: Refer to the manufacturer’s data sheet or specifications for detailed information on capacitor pin and polarity configurations.

By considering these factors, you can determine the polarity of an electrolytic capacitor. Remember to follow the manufacturer’s guidelines and markings closely to ensure proper polarity connections for safe and reliable operation.

The life of electrolytic capacitors can vary depending on several factors, including capacitor quality, operating conditions and usage habits. Although electrolytic capacitors are widely used and can provide long life, they are not considered as durable as some other types of capacitors. Here are some general considerations for an electrolytic capacitor’s lifespan:

● The lifespan of electrolytic capacitors can vary based on factors such as quality, operating conditions, and usage patterns.

● Manufacturers provide a rated life for electrolytic capacitors, which is typically stated in hours of operation at specific temperature and voltage levels.

● Operating the capacitors within the specified temperature and voltage ranges outlined by the manufacturer can help maximize their lifespan.

● Over time, the electrolyte in electrolytic capacitors can dry out or degrade, leading to a decrease in capacitance or an increase in equivalent series resistance (ESR).

● Stress factors like high temperatures, high ripple currents, or voltage spikes can impact the lifespan of electrolytic capacitors.

● The lifespan of electrolytic capacitors can range from several thousand to tens of thousands of hours.

● Periodic inspection and replacement of electrolytic capacitors, especially in critical applications, are recommended to ensure reliability.

● Always refer to the manufacturer’s guidelines, datasheets, and specifications for accurate information about the expected lifespan of electrolytic capacitors in specific applications.

So that’s about everything you need to know about integrated circuits and how they work. We at Qtech are always ready to give you solid advice about PCBs, PCBA, and ICs. Talk to us today and find out more on what we offer. With over a decade of experience in this field, you’re guaranteed quality always.