A capacitor is a component made up of two metal films placed close together and separated by an insulating material. The two pieces of metal are called pole plates, and the material in between is called the dielectric. The key reason why capacitors can be divided into different types is that there are certain differences. There are many differences not only in materials, but even in design principles, working principles and structures.

Tantalum is the second most precious metal after precious metals, and is one of the most expensive of the rare metals. Tantalum capacitors are electronic components with tantalum as the main component, small in size and high in capacity, installed on printed circuit boards of many small electrical/electronic devices such as personal computers, cell phones and digital.

Electrolytic capacitors with tantalum as a component are called tantalum capacitors. They are polarized capacitors with good frequency and stability. It has a tantalum anode and electrolytic capacitor.

Tantalum capacitors have been used in electronic circuits since the 1950’s. Today they still play an important role in many different types of electronics.

Tantalum capacitors are a kind of electronic components which is widely used in the industries. They can be found in every electronic product such as speakers and cell phones, TV and microwave oven, computer and headphone.

Tantalum capacitors are small, high-capacity capacitors. Tantalum capacitors come in various shapes and are made into small and chip components suitable for surface mounting. Tantalum capacitors are used not only in military communications, but also in aviation, aerospace and other fields, and are widely used in industrial control and vision, in frequency equipment, communication instruments and other products.

Due to the thin oxide film, the distance between the two pole plates of tantalum capacitors is very close, and there is almost no inductive reactance, which is very sensitive, so the charging and discharging speed is very fast. In addition, because there is no electrolyte inside the tantalum capacitor, it is very suitable for working under high temperature.

Tantalum capacitors are used in many different applications, including:

●Power supplies and inverters

●Radio frequency systems

●Telecommunications equipment

●Scientific instrumentation equipment (e.g., oscilloscopes)

Tantalum capacitors are a good choice for electronic applications. They are used in power supplies and other low-power devices, as they provide high capacitance while maintaining low leakage currents. They also have excellent ESR (equivalent series resistance), which means that they can withstand high voltages without affecting their performance.

Pros

Tantalum capacitors have several advantages over traditional aluminum electrolytic capacitors:

●Tantalum has better conductivity than aluminum, making it ideal for applications where heat dissipation is important (such as switching power supplies).

●It has lower drift rate than aluminum due to its higher dielectric constants (dielectric constant is the property of an insulating material that determines how easily electricity flows through it).

●You can use tantalum capacitors with no risk of arcing or explosions because there’s no need for venting holes on them—and if you do want one then you’ll be able to find one at any electronics store!

Cons

There are some disadvantages of tantalum capacitors:

●Tantalum capacitors are more expensive than ceramic capacitors, and they can be up to twice as expensive as aluminum electrolytic capacitors.

●It takes time for the capacitor to break in and get its full potential.

The Reliability:

Tantalum capacitors are reliable, and they have a longer service life than other types of capacitors. They have high current handling capability with low losses in comparison to other ceramic types such as alumina/silicon carbide (ACSR).

The low power consumption

The low power consumption is another advantage of tantalum capacitors. Since they have a low voltage drop, they require less energy to run at full capacity. This means that you will use less electricity per day than you would with other types of capacitors. Another benefit is that your system will generate less heat during operation so there’s no need for fans or cooling systems.

The high energy density

The high energy density of tantalum capacitors is a great substitute for the traditional ceramic capacitors. This is because it has a high electrical conductivity, which makes it an excellent choice for use in applications that require high power densities or large currents.

In addition to its excellent electrical properties, tantalum capacitors also have the ability to be stacked together to form larger assemblies for even greater power handling capacity. These stacking designs can be used as independent units or as building blocks toward larger projects.

Resistance to high temperatures and voltages

Tantalum capacitors have low temperature coefficients and can withstand high voltage applications without any problems, unlike the aluminum electrolytic type which has a low coefficient of thermal expansion at elevated temperatures.

Tantalum capacitor has one-way conductivity, which is called “polarity”, when using, the current should be accessed according to the positive and negative direction of the power supply, the anode (positive) of the capacitor is connected to the “+” pole of the power supply, and the cathode (negative) is connected to the “-” pole of the power supply, if the capacitor is connected wrongly, not only the capacitor can not play a role, but also the leakage current is very large, and the core will be hot in a short time, and the oxide film will be destroyed and then fail.

In general, positive polarity means positive terminal of the battery is connected to positive terminal of the capacitor while negative polarity means that it is connected to negative terminal of the capacitor.

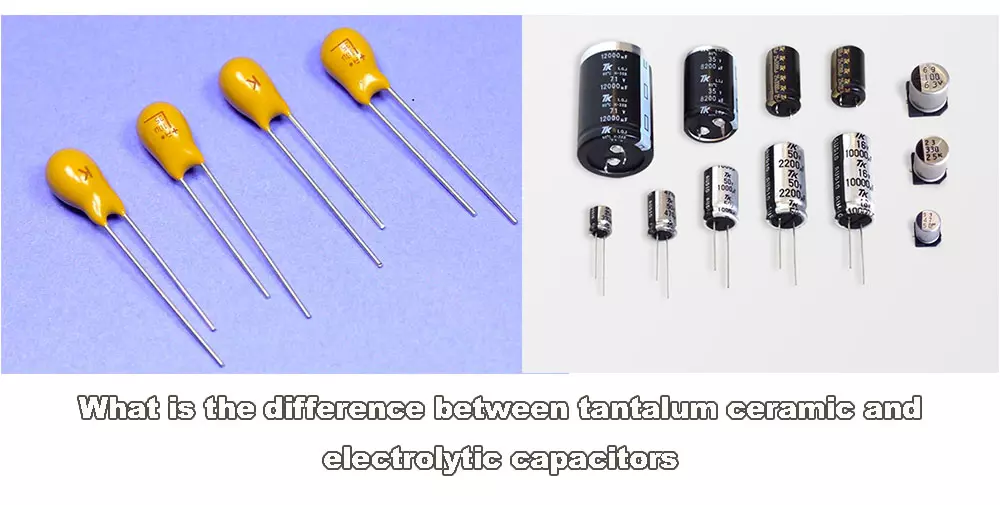

The terms “tantalum ceramic” and “electrolytic capacitors” can be used interchangeably, but they actually refer to different things.

Tantalum ceramic capacitors are made of tantalum oxide, a material that has a higher capacitance than electrolytic capacitors. . The main advantage they have over electrolytic capacitors is their durability: they won’t be destroyed by an overheating laptop or smartphone battery. Overall, however, these are still some of the best options for high-quality power supplies because they last longer without needing replacement every few years or so like other types do.

An electrolytic capacitor is a type of capacitor that uses an electrolyte solution to achieve a larger capacitance. Electrolytic capacitors have a low capacitance. They are used in many electronic devices, including laptops, cell phones, and other portable electronics. The main advantage of electrolytic capacitors is their ability to handle higher voltages. These high-voltage applications include power grid distribution systems (i.e., electric motors), as well as vehicle propulsion systems such as hybrid cars or even aircrafts! However, they have a limited lifespan compared to other types of capacitors, and can be prone to leakage or failure if not used correctly.

Tantalum capacitors are marked by letter code. The letters and numbers can be printed in different colors depending on application and indicate their characteristics and specifications.

Here is an example of a typical tantalum capacitor marking: “47µF 16V K” would indicate a tantalum capacitor with a capacitance of 47 µF, a voltage rating of 16 volts, and a tolerance of ±10%.

Here are some signs that your tantalum capacitor may be bad:

Leakage

If the capacitor is leaking or has brownish discoloration around its terminals, it may be a sign that it has failed.

Short circuit

A short circuit occurs when tantalum capacitor fails and creates a low resistance path between its terminals.

Reduced capacitance

Over time, the capacitance of tantalum capacitor can decrease, which can affect the performance of the circuit and may be detected by measuring the capacitance using a capacitance meter.

Swollen or cracked body

Tantalum capacitors can also fail due to mechanical stress or physical damage, which can cause the body to become swollen or cracked.

If you observe that your tantalum capacitor is bad or not working properly, it is recommended to replace it to avoid potential damage to the circuit or other components.

So that’s about everything you need to know about integrated circuits and how they work. We at Qtech are always ready to give you solid advice about PCBs, PCBA, and ICs. Talk to us today and find out more on what we offer. With over a decade of experience in this field, you’re guaranteed quality always.