During routine quality control testing, it is noticed that a certain batch of PCBA products had problems with solder joint air bubbles after reflow soldering. Through using automatic optical inspection (AOI) systems and X-ray equipment to detect soldering the quality and find out that there was a portion of the PCBA appeared solder joint air bubbles. So, In this article, we have three parts: what is solder joint air bubbles? What makes solder joint air bubbles occurred? And how to solve the solder joint air bubbles? Let’s find the answer in the following contents.

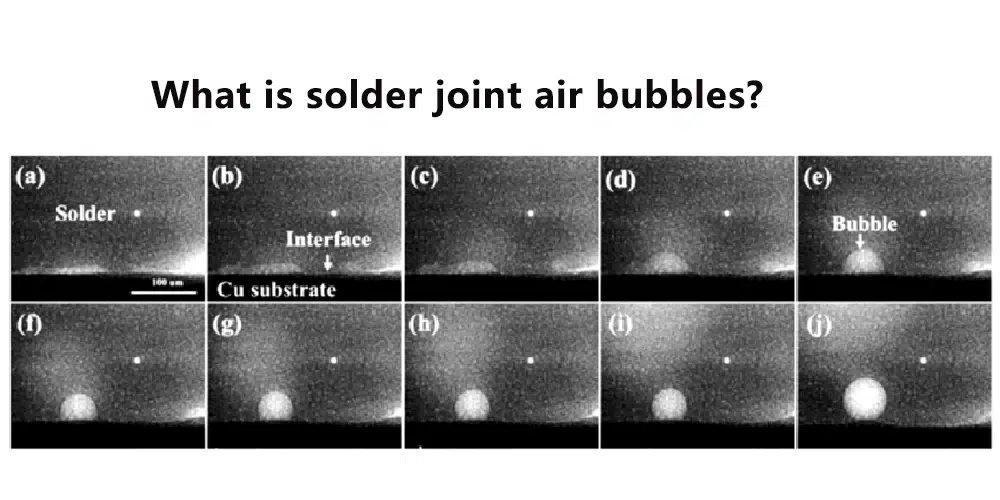

In general, when the flux residues in the solder paste and impurities on the soldering surface are not excluded from the solder joints, the air bubbles in the solder joints are formed. Excessive solder joint air bubbles bring the lower strength of solder joints lower and impact the electronic connection capability as well. The IPC standard has clearly stipulated that any solder ball void greater than 25% in the X-ray affected area is regarded as a defect.

For the PCBA process, it is common to notice that voids or air bubbles occur in solder joints. However, these solder joint voids and air bubbles may affect the strength and electrical connectivity, thereby bringing bad effects on the performance and reliability of the board.

Solder joint air bubbles in PCBA may bring the following effects:

In the PCBA process, air bubbles in solder joints are a complex problem involving many factors. The following may be the main reasons:

1. Welding parameters

Welding parameters, including temperature, time, and cooling rate, have a significant effect on air bubbles formation. Too high soldering temperature or too long soldering time may cause the flux in the solder to volatilize prematurely and form air bubbles. If the cooling rate is too fast, air bubbles may be solidified in the solder joint before they can escape. Fine tuning and control of welding parameters is essential to reduce the formation of air bubbles.

Also read: How to improve the welding reliability of QFN package bottom?

2. Solder quality

The quality of solder directly affects the quality of solder joints. Containing too much gas, moisture, or low-quality flux can cause air bubbles to form during soldering. Choosing a reliable quality solder, and storing and handling it properly can reduce the risk of air bubbles occurring.

3. PCB surface treatment

The condition of the soldering surface is also critical to solder joint quality. Air bubbles can also form if the soldering surface contains impurities, oxides, or moisture. Therefore, it is very important to ensure that the welding surface is clean and properly prepared.

There are some solutions that enable fixing this issue.

1.Identify the source of the problem

First, we need to determine how the solder joint air bubbles are formed. Possible causes include improper setting of soldering parameters (such as temperature, time, and cooling rate), solder quality problems (such as excessive gas or moisture), and PCB surface conditions (such as presence of impurities or moisture).

This may require specialized equipment and techniques, such as X-ray inspection or cross-sectional analysis, to observe and analyze the shape, location and number of bubbles.

2.Improve the welding process

Depending on the source of the problem, we may need to improve the soldering process. For example, if the problem is due to poorly set welding parameters, then we can optimize welding temperature, time and cooling rate.

If the problem is due to solder quality issues, then we may need to improve solder selection, storage and handling. If the problem is due to the state of the PCB surface, then we may need to improve the cleaning and pretreatment of the PCB.

3.Implement quality control

While improving the welding process, we also need to implement strict quality control to ensure the effect of the improvement. This may include on-line inspection (such as automated optical inspection, x-ray inspection) and off-line inspection (such as cross-sectional analysis of samples, shear strength testing).

4.Continuous improvement

Welding is a complex process that can be affected by many factors. Therefore, we need to carry out continuous improvement, regularly evaluate the welding quality, feedback and learn from mistakes, and gradually optimize the welding process.

So that’s about everything you need to know about integrated circuits and how they work. We at Qtech are always ready to give you solid advice about PCBs, PCBA, and ICs. Talk to us today and find out more on what we offer. With over a decade of experience in this field, you’re guaranteed quality always.