Flexible PCB is a relatively new technology, and it rapidly becomes the industry standard for connecting PCBs to other devices. As the world becomes more connected and more devices require wireless communication, flexible PCBs will become increasingly important.

This article will explain what flexible PCB is and how it is manufactured. It also explains the applications where these PCBs can be used in your next project.

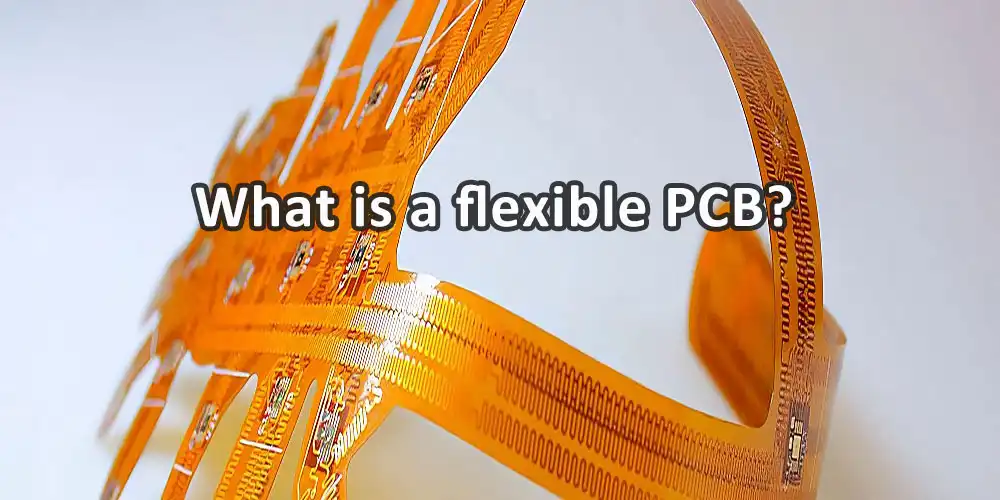

A flexible PCB is an advanced type of printed circuit board (PCB) that can be bent or curved without compromising its integrity. It is used in many different applications, including wearables, portable electronics, and mobile devices.

If we talk about its composition, flexible PCBs are made of two layers of copper foil laminated to the polymer core with adhesive. The outer layer of the board is often reinforced with glass-reinforced epoxy resin, which makes it more durable than other flexible materials like polyimide film.

The main reason to use flexible PCBs in your next project is that they allow you to make your product thinner and lighter than ever before. Also, if you’re working on something that needs to be portable or wearable, flexible PCBs are the way to go!

When it comes to flexible PCBs, there are three types you can use in your design.

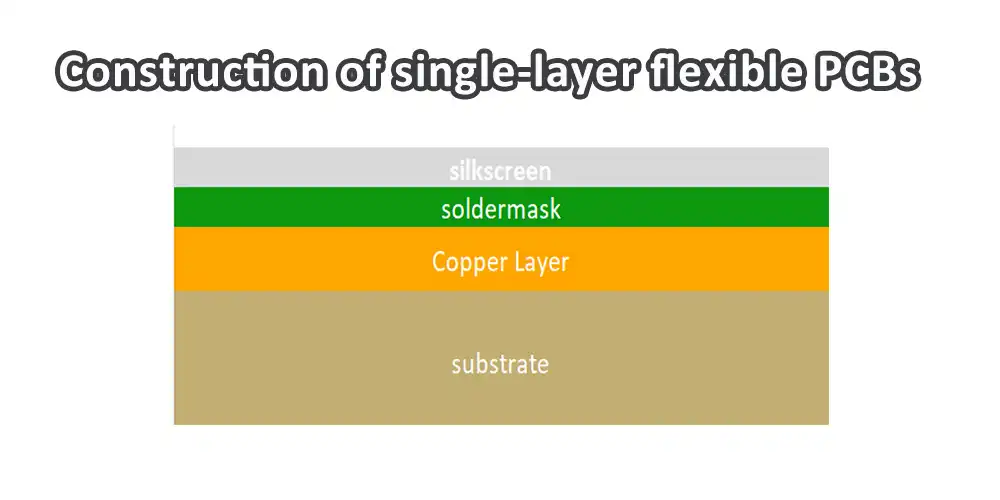

1. Single-layer flexible PCB

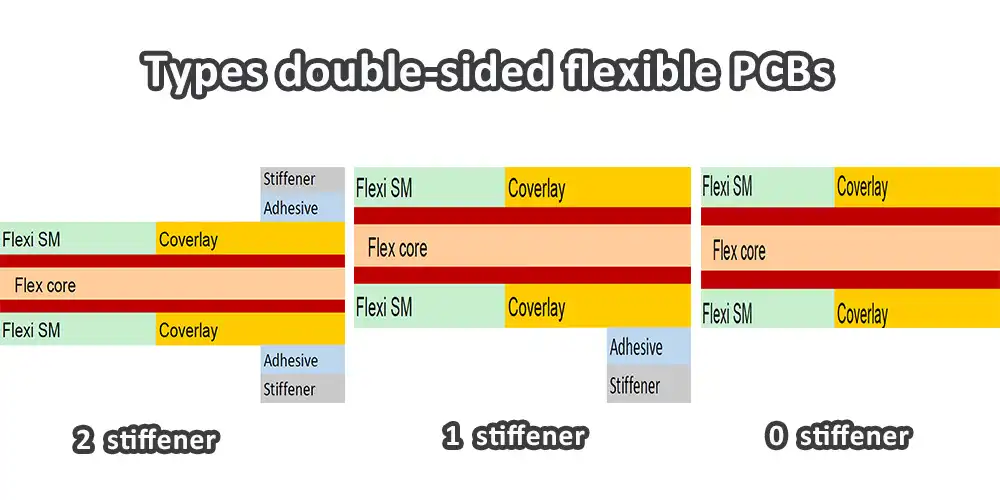

2. Double-layer flexible PCB

3. Ultra-thin flexible PCB

These are made of a thin layer of copper and they have one side that is rigid and the other that is flexible. These boards are great for projects where you want to be able to bend the board without damaging it or causing damage to the components soldered on it.

These are made of two layers of copper with a layer of insulation between them. They’re also called “Flexible Insulated Boards” (FIBs).

| Type 1 | Type 2 | Type 3 |

| Double-layer flexible PCB with 2 stiffener stack up | Double-layer flexible PCB with 1 stiffener stack up | Double-layer flexible PCB with no stiffener stack up |

These boards have an advantage over single-layer flexible PCBs because they’re more durable than their single-sided counterparts, but they’re also more expensive because of their increased thickness and complexity.

These are made from polyimide (PI) or polyamide (PA), which makes them incredibly thin—as thin as 0.2mm!

They’re also lightweight compared to other types of flexible PCBs; however, these boards tend to be more expensive because they require special equipment for manufacturing and assembly.

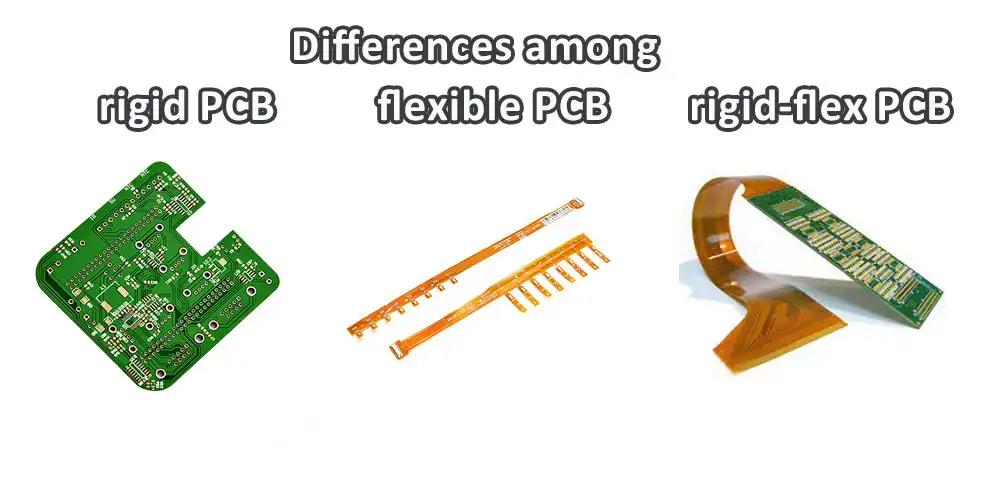

| Characteristics | Rigid PCB | Flexible PCB | Rigid-flex PCB |

| Material/composed of: | Rigid PCBs are made of rigid materials, like FR-4 and glass epoxy. | Flexible PCB is made of flexible materials like polyimide film, TPU, or other special plastic films that can be applied to a substrate layer like copper foil. | Rigid-flex PCBs are made of flexible materials and have an additional layer of rigid material applied to the top surface. |

| Used in/applications: | They’re used in applications where you need to keep your circuit boards as flat as possible. | They’re used in applications where you need to make your circuit board conform to a curved shape. | Rigid-flex PCBs are used in applications that require high thermal conductivity or flexibility. |

| Thickness: | 0.3 – 1.6mm | 0.3 – 1.6mm | 1.6 – 2.7mm |

| Minimum width/height: | 2×2 inches (5x5cm) | 2×2 inches (5x5cm) | 4x4inches (10x10cm) |

Flexible displays are the most common application of flexible PCB. They are found in many popular devices, including smartphones, tablets, and e-readers.

They can be used to create screens that can be bent, rolled up, and otherwise manipulated without damage to the underlying electronic components.

Wearable devices include devices such as smartwatches and fitness trackers.

Flexible PCBs allow these devices to be made smaller and lighter than traditional models. The wearable device market is one of the fastest-growing markets for flexible PCBs.

Smart cards are used for storing information that can be read by an electronic device. They’re most commonly used for financial transactions, identification cards, and public transit tickets.

Flexible PCBs are often used to create these smart cards because they can be bent without breaking and still function properly.

RF medical sensors refer to radio frequency communication. This type of communication is commonly used to monitor vital signs such as blood pressure, heart rate, and temperature.

A flexible PCB can be used in RF devices because it doesn’t break when bent or folded up—it just needs to be attached to other pieces of the device in order to work properly.

Flexible PCBs are used in a variety of products, from medical devices to solar panels. They offer many advantages over more traditional PCBs, including their ability to bend and flex with minimal damage.

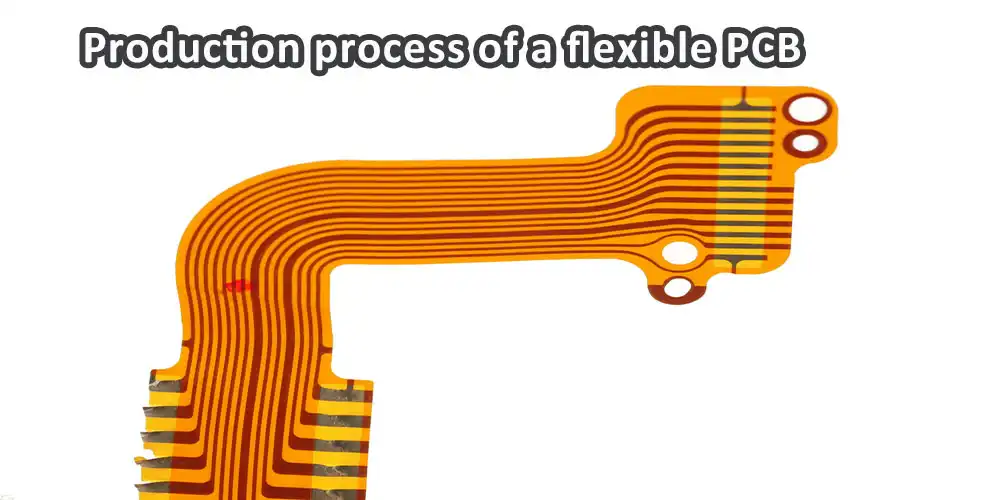

Here’s how they’re made.

1. A substrate is chosen for use in the flexible PCB circuit and cut to size.

2. The substrate is coated with a conductive material (usually copper) using photolithography or electroplating methods.

3. Components are mounted on the board and connected together at their appropriate locations using solder, wire bonding, or other methods of connecting components to each other or to a power source (if required).

4. The finished circuit is tested to ensure that it works correctly before being packaged into its final form so that it can be shipped out to customers all over the world!

The design of a flexible PCB is a multi-step process.

First, it is important to consider the material that will be used for the flexible circuit board. The type of material you choose will affect the flexibility and durability of your product.

Second, you must decide how to route signals around the board. You should also consider how many layers you want in your PCB and whether or not you will use vias.

Finally, you must determine how much space there is between components on your board so that it can be folded without damaging them.